Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

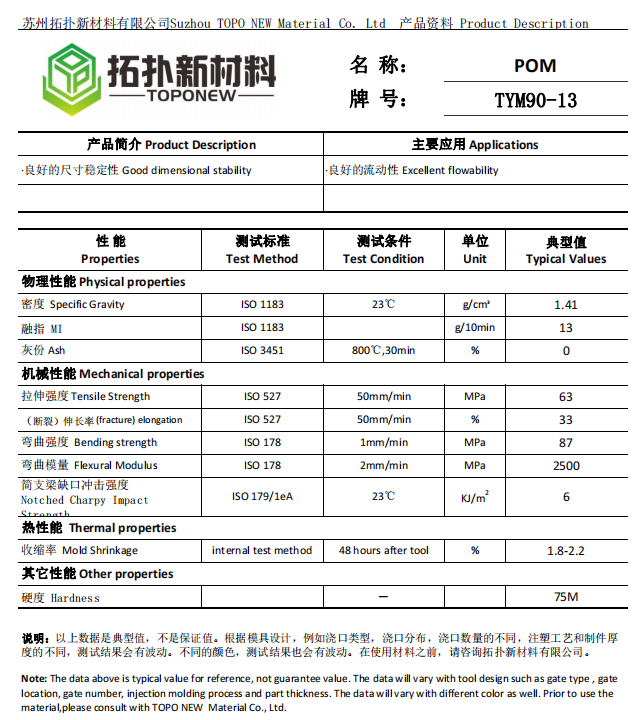

POM TYM90-13

Excellent flowability

MFR ISO 13 g/10min

(Custom materials available according to your Technical Data Sheet)

- Product Details

-

Download

Customizable Materials Available:

- Color (Customization of plastic pellet color according to your requirements.)

- Flame retardant grade (Let us know which flame retardant level you need: 0.8mm-3.0mm HB, V0, V1, V2, 5VA, 5VB)

- Glass fiber reinforcement material (10%-50% availability)

- Carbon fiber reinforcement material (10%-50% availability)

- UV resistance property (Tell us the application scenarios or UV resistance level of the materials )

- Other materials can also be customized ( Just need to provide your Technical Data Sheet. )

Technical Data Sheet of POM TYM90-13 POM Plastic Granules

POM Wear Resistance POM Plastic Raw Material Granule

High-Performance POM Plastic Pellets for Precision Engineering

Our Polyoxymethylene (POM) plastic pellets are engineered to meet the rigorous demands of industries requiring precision and reliability. As a high-performance thermoplastic, POM offers an exceptional combination of stiffness, dimensional stability, and wear resistance, making it an ideal choice for manufacturing mechanical and automotive parts, electronics, and more.

Why Choose POM?

-

Superior Mechanical Properties: POM plastic pellets provide high tensile strength and stiffness, ensuring that components made from this material exhibit excellent durability and resistance to deformation under heavy loads.

-

Low Friction & High Wear Resistance: Designed for applications involving frequent motion, POM significantly reduces friction and wear, enhancing the lifespan of parts such as gears, bearings, and conveyor belts.

-

Dimensional Stability: Even under fluctuating temperatures and mechanical stress, POM retains its shape and functionality, making it ideal for parts requiring high precision, such as automotive components and machinery parts.

-

Excellent Chemical Resistance: POM resists a wide range of chemicals, including fuels, oils, and solvents, ensuring that it remains stable in chemically harsh environments. This makes it particularly suitable for use in fuel system components, electrical connectors, and other industrial applications.

-

Good Creep Resistance: POM maintains its strength and structural integrity even when exposed to long-term loads, making it perfect for applications involving constant mechanical stress.

Typical Applications:

- Automotive Industry: Ideal for fuel system components, gears, and fasteners.

- Electronics: Used in precision parts like connectors and housings.

- Machinery: Gears, bearings, rollers, and conveyor belt components benefit from POM's low friction and wear-resistant properties.

- Consumer Goods: Handles, latches, and various other functional components.

With its exceptional balance of toughness, versatility, and performance, our POM plastic pellets deliver reliability across a broad range of applications, ensuring that your products are built to last, even in the most demanding environments.

Download

-

拓扑新材料 POM TYM90-13.pdf

Download 拓扑新材料 POM TYM90-13.pdf